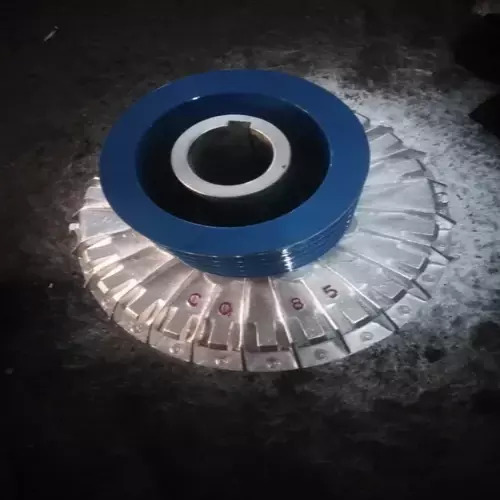

Fluid Coupling

25000 INR/Piece

Product Details:

- Connection Female

- Size Standard

- Usage Industrial

- Color Dark Blue

- Material Stainless Steel

- Surface Treatment Polishing

- Technique Casting

- Click to View more

X

Fluid Coupling Price And Quantity

- 1 Piece

- 25000 INR/Piece

Fluid Coupling Product Specifications

- Equal

- Industrial

- Dark Blue

- Stainless Steel

- Polishing

- Female

- Standard

- Casting

Fluid Coupling Trade Information

- 1 Piece Per Day

- 10-15 Days

- Wooden Boxes

- All India

Product Description

Rotating mechanical power can be transmitted by a device called fluid coupling. Also known as hydraulic coupling, this device is comprised of housing, impeller and turbine. Industries with applications involving rotational power uses this device. The industries that use it are automotive, railway and aviation. The fluid in this device absorbs misalignment of drive shaft and driven shaft. Transmission fluid is accelerated or decelerated for transferring power from one shaft to another. Fluid coupling is essential in industrial applications for protecting overloading, vibration free & noiseless power transmission. In whichever condition it is used, it ensures smooth power transmission. The fluid in this device is decided based on factors, like density, viscosity and flash points.

Fluid Coupling Specification:

- Efficiency: 0.96%

- Finish: Polished

- Range of Power Transmission: 0.05 kW

- Speed: 960 RPM

- Country of Origin: Made in India

- Frequency: 50Hz

- Usage/Application: Industrial

- Material: Stainless Steel

- Brand: Leelam Industries

Features of Fluid Coupling:

Fluid couplings offer different features that make them useful for power transmission applications. Here are some key features:

- Smooth Start-Up

- Overload Protection

- Torque Limiting

- Vibration Damping

- Maintenance-Free Operation

- Temperature Stability

- Easy Installation

- Robust Construction

- High Efficiency

- Versatility

Benefits of Fluid Coupling:

Some benefits offered by the fluid coupling includes:

- Power transmission free from vibrations and noises

- Smooth transmission in extreme condition

- Unloaded motor or engine starts

- Overload Protection

- Used in both vertical and horizontal application

- Maximum torque can be adjusted

Fluid Coupling FAQ:

Q: What is a fluid coupling?

A: A fluid coupling is a device used for transmitting torque and providing a smooth start up in mechanical power transmission systems. It consists of an output shaft, an input shaft, and a fluid filled chamber that connects the two shafts.

Q: How does a fluid coupling work?

A: A fluid coupling works based on the principle of hydro- kinetic and requires that the output speed be less than the input. The power is transmitted from one shaft to another shaft by means of acceleration and deceleration of a hydraulic fluid.

Q: What are the advantages of using a fluid coupling?

A: Fluid couplings offer several advantages, like:

- No Wear

- High Torque Transmission

- Easy to Use

- Less Complex Design

- Easy Installation and Integration

- Overload Protection

Q: Where are fluid couplings used?

A: Fluid couplings are used in automotive transmission system, marine propulsion system and in industries for power transmission. Other areas of application include:

- Belt Conveyors

- Crushers and Mills

- Marine Propulsion

- Mining Equipment

- Power Generation

- Metal Processing

- Construction Machinery

Q: Can fluid couplings be controlled or adjusted?

A: Yes, fluid couplings can be controlled or adjusted to some extent. The couplings can be adjusted on controlled in various ways such as fill level adjustment, external control devices, and fluid viscosity and temperature. It helps in altering the torque transmission characteristics. Some couplings may have external controls to vary the amount of slippage or adjust the speed torque characteristics.

Q: Is maintenance required for fluid couplings?

A: Fluid couplings generally require minimal maintenance. Periodic inspection of the fluid level, fluid condition, and alignment of the coupling is required. If the fluid shows signs of degradation or contamination, it may need to be replaced.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free