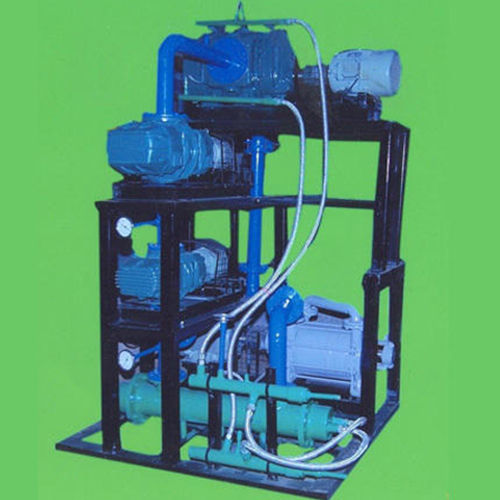

Mechanical Booster System

200000.00 INR/Piece

Product Details:

- Usage Industrial

- Equipment Type Booster System

- Material Steel

- Processing Type Standard

- Condition New

- Color Silver

- Power Mode Electric

- Click to View more

X

Mechanical Booster System Price And Quantity

- 1 Unit

- 200000.00 INR/Piece

Mechanical Booster System Product Specifications

- Booster System

- Industrial

- Standard

- New

- Silver

- 1 Year

- Electric

- Steel

Mechanical Booster System Trade Information

- 10 Unit Per Day

- 4 Days

- All India

Product Description

Mechanical Booster System is what we have to offer. They improve vacuum pump performance because low pressure operation reduces the volumetric efficiency of vacuum pumps. They allow for operation between 10 and 10-4 mbar A. The architecture of mechanical vacuum boosters ensures contact-free rotation of two figure-of-eight lobes while retaining extremely close clearance, allowing them to handle massive volumes of gas with relatively little power usage. There is no oil inside the vehicle. We provide the entire system, along with the principal pump (Backing Pump) and instrumentation needed to carry out automatic or semi-automatic tasks, to satisfy specific needs.

Mechanical Booster System Specifications:

- Pump Speed: 30 To 2500 Lbm

- Frequency: 50 Hz, 60 Hz

- Motor Power: 11 To 75 KW

- Bore: 200 Mm

Mechanical Booster System Features :

Mechanical Booster System (MBS) comes with a variety of features that enhance its performance and make it suitable for specific applications. Here are some key features of MBS:

- Multi-stage Design: MBS has a multi- stage design with multiple impellers or rotors in the booster pump. It allows for efficient compression and evacuation of gas and hence increased pumping capacity and speed.

- Synchronization: The impellers or rotors in the booster pump are synchronized for maintaining a precise clearance between them and the housing for smooth operations and reduced risk of contact or damage between the components.

- Gas Cooling: Many MBSs include provisions for gas cooling like cooling jackets or water circulation, that help in dissipating heat generated during compression and also improving the overall efficiency of the system.

- Integrated Control and Monitoring: MBSs have integrated control and monitoring systems that allow for real time monitoring of vacuum levels, pump operation, and other relevant parameters.

- Variable Speed Drive: Variable speed drives in MBSs allow for adjustable pumping speed, enabling flexibility to match the specific requirements of the application.

- Gas Ballast Option: Gas ballast is a feature found in certain MBSs, particularly for pumps handling water vapor or condensable gases. It helps in preventing condensation and the associated issues by introducing a controlled amount of dry gas during compression.

- Compact Design: MBSs are compact for easier integration into existing vacuum systems or limited space environments.

- Material Compatibility: MBS components are constructed from materials that are compatible with a variety of gases and process conditions.

- Safety Features: MBSs may include several safety features, such as overheat protection, overload protection, and interlocks for preventing damage to the system or ensuring safe operation.

- Serviceability: MBSs are designed for facilitating ease of maintenance and service.

Benefits of Mechanical Booster System:

Mechanical Booster Systems come with a plenty of benefits which are as follows:

- Increased Pumping Speed: The primary advantage of an MBS is its ability to significantly increase the pumping speed of a vacuum system. It enhances the overall pumping speed, and enables faster evacuation and reduces pumpdown times.

- Higher Vacuum Levels: MBSs help in attaining higher vacuum levels by enhancing the pumping capacity, and hence allowing for deeper vacuum levels in the system.

- Handling Large Gas Loads: MBS can handle large volumes of gas efficiently and is suitable for applications that involve high gas flow rates or rapid gas evacuation.

- Versatility and Flexibility: MBSs are versatile and can be integrated into different vacuum systems and processes.

- Improved Process Efficiency: By increasing pumping speed and achieving higher vacuum levels, MBS contributes to improved process efficiency.

- Energy Savings: While MBS requires additional power compared to standalone primary pumps, it can still result in energy savings in various scenarios.

- Compact Design and Space Savings: MBS is compact in design and can be easily integrated into existing vacuum systems or limited space environments.

- Reliability and Durability: MBSs are known for their durability and robustness as they can handle challenging operating conditions, such as high gas loads and frequent cycling.

- Application Compatibility: MBS is suitable for a variety of applications, such as semiconductor manufacturing, research laboratories, vacuum coating, and industrial processes.

- Process Control and Consistency: With their increased pumping speed and higher vacuum capabilities, MBS contributes to improved process control and consistency.

FAQ for Mechanical Booster System:

Q: What is a Mechanical Booster System (MBS)?

A. Mechanical Booster System (MBS) is a configuration of vacuum pumps used for increasing the pumping speed and performance of a primary vacuum pump. It is used to enhance the overall capabilities of the vacuum system.

Q: What are the applications of Mechanical Booster Systems?

A. MBS finds application in semiconductor manufacturing, Vacuum Coating, Research and Development, Vacuum Furnaces, Aerospace and Space Simulation, Industrial Processes and Large-Scale Vacuum Systems.

Q: How does a Mechanical Booster System work?

A. A MBS works by combining the pumping capabilities of a primary vacuum pump and a mechanical booster pump for enhancing the overall performance of the vacuum system.

Q: What are the advantages of using a Mechanical Booster System?

A. Some keys advantages of MBS are:

- Increased Pumping Speed

- Higher Vacuum Levels

- Handling Large Gas Loads

- Versatility

- Improved Process Control

- Reliability and Durability

- Scalability

Q: Are there any limitations or considerations for using Mechanical Booster Systems?

A. One must consider the following while using MBS:

- Higher Initial Cost

- Space and Installation

- Maintenance and Service

- Noise and Vibration

- Limited Vacuum Range

- Gas Compatibility

- Power Consumption

Q: How do I select the right Mechanical Booster System for my application?

A. Choosing the appropriate MBS involves considering factors such as identify application requirements, evaluate vacuum level, assess gas load, compatibility, space and installation, maintenance and service, energy efficiency, consult with experts, compare options and cost considerations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free